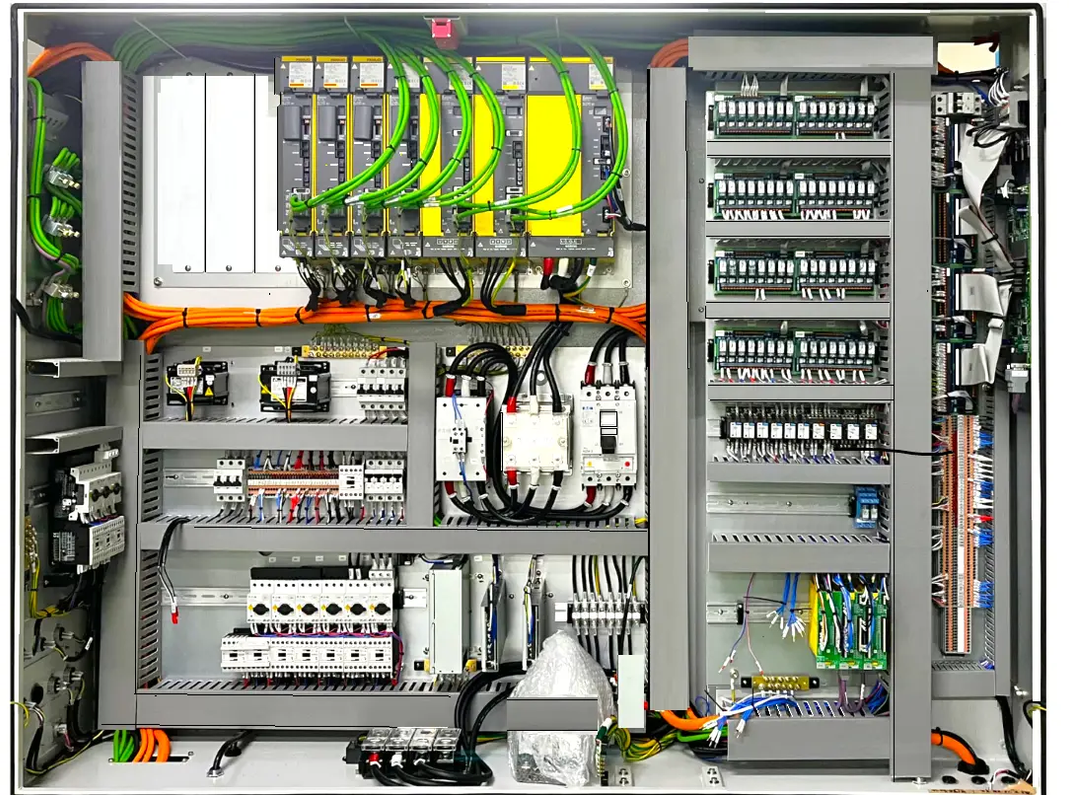

How to Build a Noise-Resistant Control System: Wiring Matters More Than You Think

When it comes to building a stable and noise-resistant control system, wiring is one of the most critical—and often overlooked—factors. Even the best PLC or controller can behave unpredictably if the wiring layout is poorly designed.

Below are practical wiring guidelines commonly recommended by PLC manufacturers to reduce electrical noise and improve system reliability in control panels.

Below are practical wiring guidelines commonly recommended by PLC manufacturers to reduce electrical noise and improve system reliability in control panels.

Recommended Wiring Guidelines

1) Use thick power cables and twist them

Use power lines that are as thick as practical and twist them together. Twisting helps reduce electromagnetic interference (EMI).

2) Keep transformer secondary wiring short and twisted

Twist the transformer secondary wiring and route it to the PLC using the shortest possible path to minimize noise pickup.

3) Always connect the ground on your SMPS

Do not leave the ground terminal of your switching power supply (SMPS) floating. Proper grounding improves stability and noise suppression.

4) Never mix AC and DC lines in the same wire duct

Route AC input/output lines separately from DC power and signal lines. Do not combine them in one duct.

5) Separate signal lines from power lines

Keep signal and power cables in separate ducts and maintain at least 20 cm (8 inches) of distance whenever possible.

6) Keep high-current devices away from the PLC

Place contactors, relays, breakers, and other high-current components as far from the PLC as possible.

7) Always operate components within their rated limits

Connect loads within the rated capacity of each component to reduce heat and prevent unexpected failures.

8) Manage heat inside the control panel

Install cooling fans and design airflow to exhaust hot air out of the enclosure, especially for summer conditions.

9) Maintain spacing between wire ducts and the PLC

Avoid mounting wire ducts too close to the PLC. Keep about 10–20 cm (4–8 inches) of space to reduce noise coupling and improve heat dissipation.

Use power lines that are as thick as practical and twist them together. Twisting helps reduce electromagnetic interference (EMI).

2) Keep transformer secondary wiring short and twisted

Twist the transformer secondary wiring and route it to the PLC using the shortest possible path to minimize noise pickup.

3) Always connect the ground on your SMPS

Do not leave the ground terminal of your switching power supply (SMPS) floating. Proper grounding improves stability and noise suppression.

4) Never mix AC and DC lines in the same wire duct

Route AC input/output lines separately from DC power and signal lines. Do not combine them in one duct.

5) Separate signal lines from power lines

Keep signal and power cables in separate ducts and maintain at least 20 cm (8 inches) of distance whenever possible.

6) Keep high-current devices away from the PLC

Place contactors, relays, breakers, and other high-current components as far from the PLC as possible.

7) Always operate components within their rated limits

Connect loads within the rated capacity of each component to reduce heat and prevent unexpected failures.

8) Manage heat inside the control panel

Install cooling fans and design airflow to exhaust hot air out of the enclosure, especially for summer conditions.

9) Maintain spacing between wire ducts and the PLC

Avoid mounting wire ducts too close to the PLC. Keep about 10–20 cm (4–8 inches) of space to reduce noise coupling and improve heat dissipation.

Final Thoughts

Most mysterious system failures are caused by noise, heat, and wiring layout issues rather than bad hardware.

Following these wiring practices can significantly improve the stability, reliability, and lifespan of your control system.

Following these wiring practices can significantly improve the stability, reliability, and lifespan of your control system.

Jan 27th 2026

Recent Posts

-

24/7 Real-Time Technical Support: Launching Our AI Assistant Service!

Hello, this is Comfile Technology. At Comfile Technology, we have always strived to provide the fa …Feb 24th 2026 -

CPi Panel PC Lite Models are Upgrading to 32GB SD Cards

The standard SD card capacity for CPi Panel PC (Lite models) is being upgraded from 8GB to 32GB. Mov …Feb 7th 2026 -

Introducing the New CFNET Field I/O

We are pleased to introduce our new CFNET Field I/O product. This product has been in development f …Jan 31st 2026