CHC-070WR - 7" Water-Resistant Human Machine Interface (HMI) Panel PC

- SKU:

- H00041

- Shipping:

- Calculated at Checkout

Description

ComfileHMI Panel PCs are WYSIWYG-based development platforms designed specifically for HMI projects. They provide flexible interfacing with a wide range of PLCs and microcontrollers, including CUBLOC, MOACON, FADUINO, MODPORT, and virtually any controller supporting Modbus communication.

Unlike conventional panel PC solutions, ComfileHMI supports Comfile Studio, a dedicated HMI design software. With an intuitive, presentation-style interface similar to creating slides in PowerPoint, users can easily design and build user interface screens without extensive coding. This significantly reduces development complexity and enables rapid project completion.

Comfile Studio and the ComfileHMI product family were first released in 2014 and have been continuously maintained with regular updates and improvements. As a result, the platform has achieved a high level of stability and reliability. Today, ComfileHMI is widely used as a UI solution by numerous companies and is actively supplied to markets worldwide.

Looking to develop a product with a professional user interface in a short time? ComfileHMI is a solution well worth considering.

- Certifications :

- Supports Modbus RTU, ASCII, and TCP

- Water-resistant and open-frame models are available

- No branding on the hardware front panel (logo-less)

- Supports TrueType fonts and Unicode for multilingual UI design

- Supports PNG, JPG, and BMP image files

- Water-resistant front panel models support audio output (WAV files)

- microSD card support for additional memory

- Supervisory remote control over Ethernet

- Remote scripting support

- SD card not required for execution (stored on eMMC), required for logging

| MODEL | CHA-043PR | CHA-070PR | CHA-070WT | CHA-070WR | CHA-102WR | CHC-070WR |

| Processor / Memory | 32bit ARM926EJ-S 400MHz, SDRAM 128MB, NAND Flash 256MB | ARM Cortex Dual 1GHz, SDRAM 1024MB, eMMC 4GB | ||||

| Case | Open-frame | Water-resistant front panel | ||||

| Communication | RS232C ×1 | RS232C ×2, RS485 ×1 | ||||

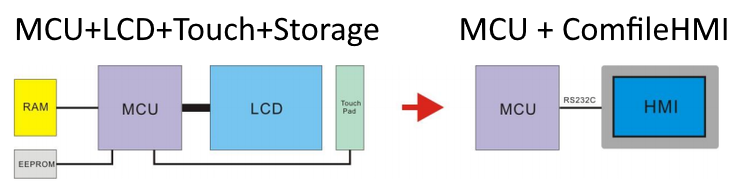

If you are designing with MCU + LCD, ComfileHMI offers an attractive solution. Using the Simple-MODBUS source code for the MCU, it can be quite easy to give an MCU a graphical user interface. We provide Simple-MODBUS source code for ARM, PIC, and AVR MCUs.

Q: Can HMIs from other vendors connect directly to an MCU?

A: In theory, yes—but in practice, it’s not that simple. HMIs from vendors like Allen-Bradley or Siemens are designed with factory automation in mind. Because of that, they expect the device on the other end to support the full Modbus function set.

What this really means is that your MCU has to implement every Modbus function the HMI might request. Only then can it properly respond to all HMI queries. For an MCU engineer, that’s a heavy and often unreasonable burden.

ComfileHMI takes a very different approach. We introduced a concept called Simple Modbus.

Instead of requiring full Modbus compliance, Simple Modbus supports only the six essential functions needed for real-world HMI operation—primarily bit and word read/write operations. This dramatically reduces the amount of code required on the MCU side.

As a result, MCU development becomes much simpler, faster, and more reliable. To make things even easier, we also provide ready-to-use sample source code for MCUs.

FAQ

Q: I don’t really see why ComfileHMI is necessary. Can’t I just build everything in C# on a PC?

A: That’s a very common question—and many engineers start exactly that way. C# is popular, and PC-based systems are widely used. However, the first major challenge these projects usually face is communication stability.

Any PC-based system used in automation inevitably has to communicate with field I/O or PLCs. Making those connections reliable is something you must solve entirely in code—handling protocols, timing, retries, exceptions, and edge cases on your own. This quickly becomes a significant engineering burden.

HMI products solve this problem differently. They already provide a proven, well-tested communication layer. Instead of writing everything from scratch, you simply match the device to an existing protocol and move on.

On top of that, screen design is dramatically easier. Creating and modifying user interfaces is fast and intuitive, with no need to build UI frameworks or custom tools in C#.

All of this leads to one important result: shorter development time. And in product development, time is money. By reducing development time, you lower labor costs and can bring your product to market much faster—often making the difference between a project that succeeds and one that stalls.